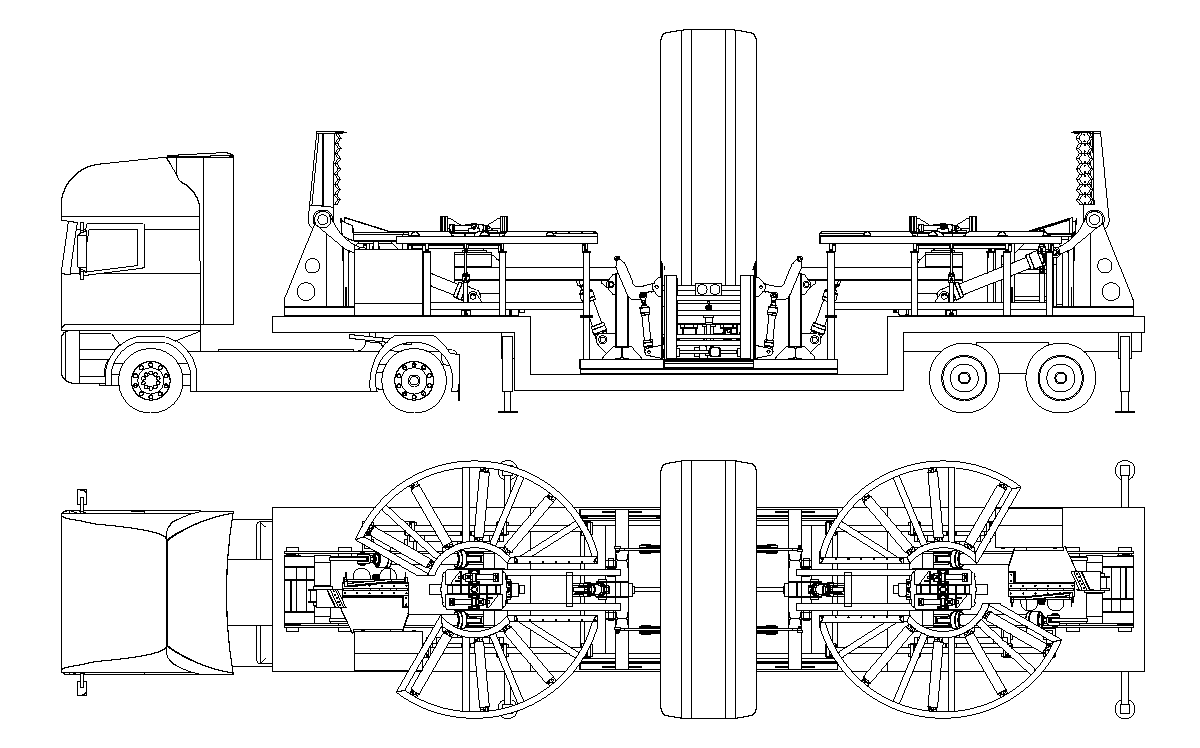

The first “mobile, compact, integrated and cost-effective” OTR tires downsizing machine

The first “mobile, compact, integrated and cost-effective” OTR tires downsizing machine

The highly innovative and focused project is aimed at solving a significant problem in the field of recycling and disposal of OTR tires for mining vehicles, with a simple but effective idea, based on the integration between a machine for their reduction and a mobile unit. The volumetric dimensions of the tires of mining vehicles make their management, transport and storage very complex. The economic impact and the risks to the environment can be minimized by introducing the HYPERTYM™ machinery upstream of the disposal process operated by recycling plants, where the tire is selected, shredded, granulated, deferred and screened according to the intended use. Discarded OTR tires are among the most bulky waste in the world with consequent high costs for their transport. In addition to their size and demanding handling, OTR tires can cause fires with consequent environmental pollution.

HYPERTYM™ will let the recycling cycle start and transform the most bulky waste into new raw material completing the so-called circular economy. Deposits of OTR tires can be easily reached over the extensions of the mining yards, reducing and optimizing transport and connected costs, achieving environmental issues requested by an increasing number of governments and stakeholders worldwide.

The HYPERTYM™ solution can easily be adapted to all types of trailers standards, either European, American, Asiatic or Russian.

The solution is the evolution of the fixed plant developed and delivered in Colombia in 2015.

HYPERTYM™

- First integrated mobile unit for OTR tire downsizing

- Based on the experience of the first OTR stationary unit

- Processable dimension of OTRs from 49” up to 63”

Integrated processing cycle within 25 minutes time each tire (based

on 63” tire)Production capacity in terms of weight = 8-10 MT (metric tons) in 1 hour

System will comply to all standard trailers worldwide

Fully automatic, dedicated handling software

innovative design getting fast, easy and safe the downsizing of giant tires

Mobile and compact

Easily relocated in the mining areas

Time and Cost-Effective

| Description | Value |

|---|---|

| tot, lenght of trailer | 13,50 m |

| tot. width of trailer | 2,55 m |

| tot. height of trailer with structure | 3,5 m |

| tot. weight of HYPERTYM™ system: trailer + hydraulic oil | 27.000 kg |

| HYPERTYM™ system | 90 KW (2 x 45 KW) hydraulic engines |

| driven by | external power unit (diesel generator / truck engine with suitable adaptor) |

| cutting units |

|

| cutting cycle after positioning of tire | 25 min |

| average production with charging and discharging time | 2 x 63 OTR mining tire hour |

| minimum size of tire | 49″ OTR mining tire |

| cutting speed and cycle | slices of 100Kg each (calculated on the tire dimension) |

| HYPERTYM™ process | fully automatic |

tot, lenght of trailer

13,50 m

tot. width of trailer

2,55 m

tot. height of trailer with structure

3,5 m

tot. weight of HYPERTYM™ system: trailer + hydraulic oil

27.000 kg

HYPERTYM™ system

90 KW (2 x 45 KW) hydraulic engines

driven by

external power unit (diesel generator / truck engine with suitable adaptor)

cutting units

- central cutting knives

- reversable slicing shears left/right

- counter knives left/right

cutting cycle after positioning of tire

25 min

average production with charging and discharging time

2 x 63 OTR mining tire hour

minimum size of tire

49″ OTR mining tire

cutting speed and cycle

slices of 100Kg each (calculated on the tire dimension)

HYPERTYM™ process

fully automatic

Contact Us for more information